Tel : 0086 372 5965149 (China)

Fax : 0086 372 5951936 (China)

Email : info@maizemiller.com

Add : Suite C, 4/F, Jinhao Business Bld., Renmin Rd. Anyang,Henan,China

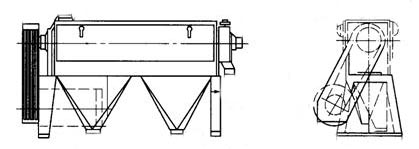

Horizontal Degerming Machine

Consistent product quality with minimal fines

Thanks to gentle treatment of the product, the germ, epidermis and endosperm are neatly separated with minimal quantities of fines. This results inpure, first-class products of consistently high quality.

Flexible degermination delivers high value for money

As a result of intensive processing between the roll rotor and screen jacket as well as the appropriate setting of the retarding pressure at the outlet, a high degree of degermination is achieved – resulting in maximum yield of the main product.

The production of certain products – e.g. flaking grits – requires wet degermination. The MHXM-M maize degerming machine is also suitable for use in this process, and the MHXM-G degerming machine of allows the germ to be extracted as a whole particle and integrated in the value-added chain.

Low fat content through dry degermination

Through the dry degermination process, the degerming machine MHXG ensures the kernel with low fat content remains after the degermination process is completed.

During dry degermination, the product does not come in contact with water. This offers a hygienic advantage as compared to wet degermination.

Pre-conditioning without steam lowers costs

The highly efficient dry degermination carried out by the MHXG offers the user further advantages: Since the process requires neither adding water nor pre-conditioning with steam, operating and investment costs are reduced.